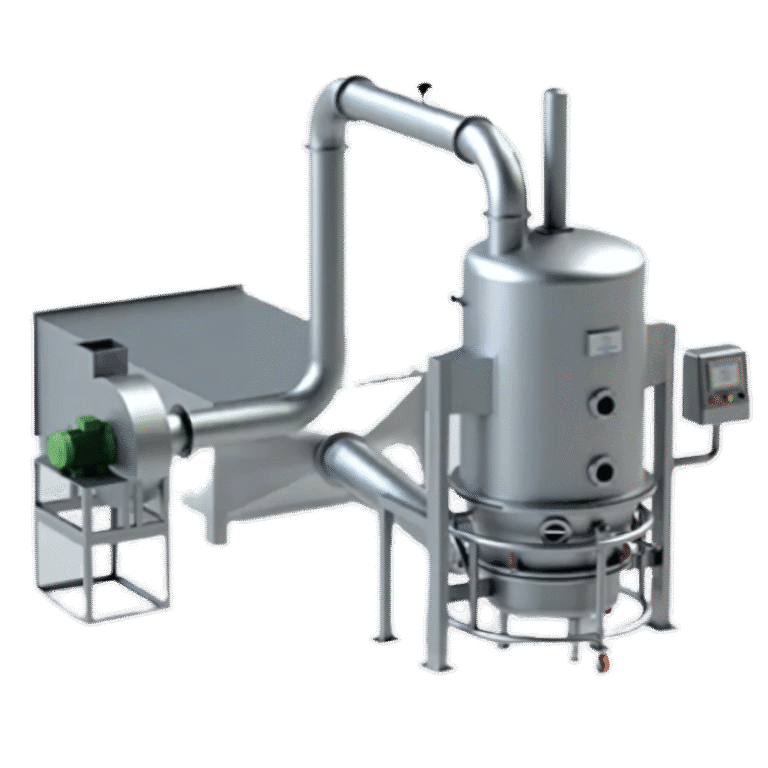

PHARMACHEM COSMETICS INDUSTRIES is a trusted Fluid Bed Dryer manufacturer in Andaman and Nicobar Islands, delivering high-performance FBD systems designed for fast, uniform, and energy-efficient drying of powders, crystals, and medium-sized pellets. Our Fluidized Bed Dryers are suitable for pharmaceutical, chemical, food processing, agrochemical, and allied industries operating across the Andaman and Nicobar region.

Our advanced Fluid Bed Dryer (FBD) machines in Andaman and Nicobar Islands use controlled hot-air fluidization technology to ensure uniform heat distribution, excellent thermal efficiency, and consistent product quality without overheating. These systems support multiple processes including drying, granulation, agglomeration, and coating of particulate materials.

PHARMACHEM COSMETICS INDUSTRIES supplies durable, GMP-compliant Fluid Bed Dryers in Andaman and Nicobar Islands that are easy to operate, low in maintenance, and engineered for reliable long-term performance. Our FBD solutions help manufacturers improve process efficiency, reduce drying time, and maintain consistent batch quality even in challenging operating environments.

With a commitment to quality engineering and customer satisfaction, we have become a preferred supplier of Fluid Bed Dryer solutions in Andaman and Nicobar Islands, offering dependable equipment that meets industry standards and delivers superior processing results.

Fluid Bed Dryers coat powders, granules, or tablets by spraying liquid onto fluidized material under carefully controlled operating conditions. This precise processing ensures uniform coating, consistent drying, and full cGMP compliance, making these systems ideal for exporters and suppliers in India.

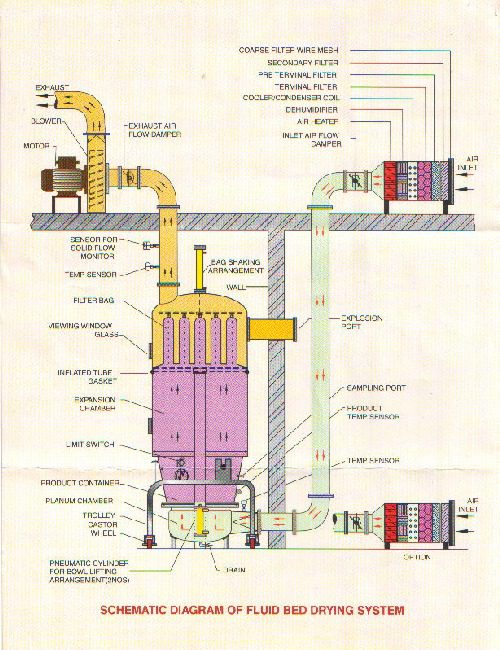

The wet material is loaded into a product container fitted with an air distributor plate and Dutch weave mesh. This design promotes uniform airflow and stable fluidization, allowing the material to move freely and evenly throughout the drying chamber.

Incoming air passes through a multi-stage filtration system that includes a coarse filter, a 5-micron filter, and a HEPA filter. The filtered air is then heated using steam or electrical heaters before entering the drying zone, ensuring clean and controlled processing.

Hot, purified air flows through the container, creating continuous motion of particles. This enables rapid heat transfer, faster drying cycles, and minimal heat loss, while a filter bag assembly prevents fine particle escape and maintains product quality.

Fluidized Bed Dryers are widely used across a broad range of industries, including food, animal feed, fertilizers, pharmaceuticals, plastics, and chemical processing. Their versatility, energy efficiency, and consistent performance make them a preferred solution for diverse industrial applications.

- Appropriate for drying humidity from powder raw material in Pharmaceutical, foodstuff, feed, chemical industries, etc.

- Semi-liquid materials, large granules, small blocks, and adhesive substantial.

- The material volumes differ during the drying process.

- Option available for either Steam-Heated or Electric Heated Blower.

- Fluid bed Dryer can be supplied with Upgradation to be used as a workstation (Vertical Spray Granulation)

- Pharmaceutical granules or crystals comprising free moisture can be easily dried as per customer’s requirement.

- Versatile Process Equipment ensuring Uniform and Efficient Drying of Products.

- Option available for CGMP Model with Documentation (IQ, DQ, PQ, OQ)

- Minimum Supervision and More Hygienic.

- Product Container features a Lifting and tilting device for convenient Handling.

- Capacity Offered from 5 Kgs to 500 Kgs.

- FLP Models Available as Option.

- MOC S.S. 304/ 316/ 316L.

Fluid Bed Dryer No. of KGS we manufacturer

- 5 KGS TO 600 KGS FLUID BED DRYE

- FLUIDIZED BED DRYER

- FLUID BED DRYER

- FBD

- Fluid bed dryer manufacturers in India

- Fluid bed dryer manufacturer in Mumbai

- Fluid bed dryer manufacturer in Gujarat

Technical Specifications

| MODEL NO. | PCI FBD 3 | PCI FBD 5 | PCI FBD 15 | PCI FBD 30 | PCI FBD 60 | PCI FBD 120 | PCI FBD 150 | PCI FBD 200 | PCI FBD 250 | PCI FBD 300 | PCI FBD 400 | PCI FBD 500 | PCI FBD 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working Capacity (Ltrs) | 9 | 18 | 45 | 90 | 170 | 290 | 350 | 475 | 575 | 675 | 900 | 1110 | 1330 |

| Max. Working Volume (Ltrs) | 6 | 10 | 30 | 60 | 120 | 240 | 300 | 400 | 500 | 600 | 800 | 1000 | 1200 |

| Batch Size (Kg) Min. & Max. | 2 - 3 | 4 - 5 | 10 - 15 | 20 - 30 | 50 - 80 | 80 - 120 | 100 - 150 | 150 - 200 | 200 - 250 | 200 - 300 | 300 - 400 | 400 - 500 | 500 - 600 |

| Blower Motor HP | 2 | 3 | 5 | 5 | 10 | 20 | 20 | 25 | 25 | 25 | 30 | 40 | 40 |

| Air Flow (CFM) | 270 | 350 | 550 | 750 | 1100 | 1900 | 2000 | 2588 | 2700 | 3235 | 3824 | 4412 | 5500 |

| Air Flow (m³/Hrs) | 460 | 595 | 935 | 1275 | 1870 | 3230 | 3400 | 4400 | 4590 | 5500 | 6500 | 7500 | 9350 |

| Steam Pressure (Kg/cm²) | 3.5 | ||||||||||||

| Consumption (Kg/Hrs) | |||||||||||||

| Steam | 26 | 36 | 45 | 90 | 130 | 150 | 186 | 216 | 244 | 344 | 344 | 344 | 344 |

| Electrical Heater (kW) | 9 | 12 | 18 | 20 | 36 | NA | NA | NA | NA | NA | NA | NA | NA |

| Compressed Air Pressure (Bar) | 6.0 | ||||||||||||

| Drying Temperature (°C) | 27 - 80 °C | ||||||||||||

| Electrical Supply | 3 Ph. AC | ||||||||||||