ointment manufacturers in india

In the growing pharmaceutical and cosmetic market of India, finding trustworthy ointment manufacturers in india is critical for brands and private label clients alike. Whether you’re searching for ointment manufacturers in Thane, ointment manufacturers in Ahmedabad, ointment manufacturers in Mumbai, ointment manufacturers in Pune, ointment manufacturers in Delhi, ointment manufacturers in Vasai, ointment manufacturers in Hyderabad, ointment manufacturers in Bharuch, ointment manufacturers in Vadodara, ointment manufacturers in Kolkata, ointment manufacturers in Chennai, ointment manufacturers in Ankleshwar, ointment manufacturers in Bengaluru, ointment manufacturers in Jaipur, ointment manufacturers in Dahej, or ointment manufacturers in Maharashtra, ointment manufacturers in india generally, this guide will help you understand what to look for, where the hotspots are, and why a quality manufacturing partner matters.

Contact us today for pharmachemcosmetics guidance and detailed product information. +91-8369524009

Why Choosing the Right Ointment Manufacturer Matters

When you engage a manufacturer for ointments, creams or topical products, you’re not just signing up for production — you’re staking your brand reputation on process, compliance, quality, packaging and logistics. A few factors to check:

Compliance with Good Manufacturing Practices (GMP) / cGMP standards.

Facilities capable of handling semi-solids, emulsions, ointments with the right vessels, vacuum pumps, transfer systems (as noted by equipment specialists).

Capacity and flexibility: ability to scale from small batches to full commercial runs.

Geographic location and supply chain advantages (for raw materials, finished goods distribution, export readiness).

Regulatory support, especially if you serve export markets.

The company Pharmachem Cosmetics Industries, for example, is known to supply ointment manufacturing plants and machinery, demonstrating the technical depth behind the manufacturing side.

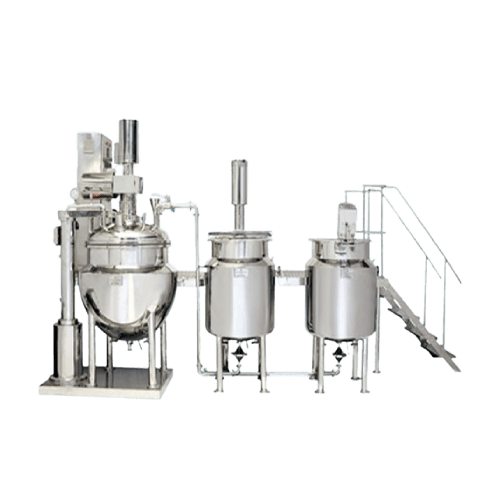

In the dynamic Indian personal care and pharmaceutical manufacturing space, investing in a robust semi-solid/ointment/cream manufacturing plant is critical for brands, private-label operators and contract manufacturers. The ointment manufacturing plant offered by Pharmachem Cosmetics Industries is designed to deliver high-quality, versatile production for ointments, creams, lotions, topical gels and related formulations.

Features of the Ointment Manufacturing Plant

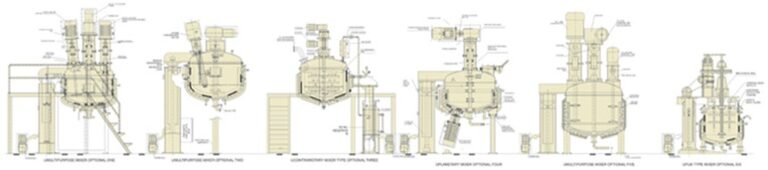

The plant offering includes a complete line designed for ointment/semi-solid production. Some of the highlights:

Multi-purpose processing vessel(s) and homogenisation equipment capable of producing ointments, creams, lotions and emulsions.

High-grade stainless steel (SS316L) contact parts and hygienic design for pharmaceutical-/cosmetic-compliant production.

Capacity range covering small batches to larger industrial volumes (for example capability from 10 kg up to 5,000 kg per batch) in many machines.

Integration with ancillary equipment: contra-rotary mixers, inline homogenisers, vacuum dryers/tray dryers etc. This enables blending, emulsification, heating/cooling, batch transfer and finishing.

Tailored for cGMP / GMP grade manufacturing environment (i.e., hygienic, cleanable surfaces, validation design).

Why Choose This Ointment Plant: Key Benefits

Here are the major reasons to go with this kind of offering (especially from Pharmachem) which make it a strategic investment for your brand or contract manufacturing business:

Versatility of Products & Formulations

Because the plant is designed not just for one type of ointment, but creams, emulsions, lotions and gels, you gain flexibility. You can diversify your product range without separate major investments. This is a big plus if you are launching multiple lines (e.g., cooling gel, anti-inflammatory ointment, cosmetic cream, herbal balm, etc.).Scalability & Cost Efficiency

With capacities starting from relatively small batches (say ~10 kg) growing to industrial sizes (thousands of kg), the plant supports growth — from pilot runs to full commercial production. This means you don’t outgrow your equipment quickly. The economies of scale help reduce cost per unit as you scale.Quality & Compliance

The use of SS316L, hygienic design and proven equipment reduces risk of contamination, improves cleanability and ensures regulatory fitness (for both pharma and cosmetic markets). This is important for tendering, export, and large-scale production.Turnkey / One-Stop Solution

Because the equipment list comes with mixing, homogenization, filling/packaging ready interfaces, you save time and effort in integrating multiple vendors. A single supplier means simplified project management, faster commissioning and fewer integration risks.Location & Support

Being based in India (Mumbai/Maharashtra) means easier access to engineering support, spare parts, local service, and lower logistic/installation cost compared to importing entire systems. Also proximity to major pharma/cosmetics hubs means you benefit from ecosystem advantages (raw materials, regulatory support, skilled workforce).Brand Positioning & Speed to Market

With right equipment you can launch your products faster. If your formulation, pilot runs and production line are ready, you reduce time-to-market. That gives you competitive edge when responding to market trends (e.g., herbal anti-inflammatory ointment, new cosmetic balm, etc.).

How This Helps Your Business (and Your Clients)

Private Label / Contract Manufacturing: If you operate as a contract manufacturer, having this kind of plant means you can attract multiple clients (pharma OTC, cosmetic brands, herbal startups) because you can handle different formats and volumes.

In-House Brand Development: If you have your own brand (cosmetic, wellness), owning or contracting this plant lets you control production cost, quality and timelines. You can experiment with niche products (premium herbal ointments, value-packs, export versions).

Export Readiness: The equipment and design allow you to meet stricter standards (for example for Middle East, Africa, Southeast Asia markets). Because the plant is built for compliance, you minimise risk of regulatory rejection.

Operational Efficiency: The integrative design and scalable capacity mean you can optimise manpower, reduce changeover time between batches, and manage variations in formulations with ease. That improves margins and flexibility.

Marketing Advantage: Being able to say “manufactured in state-of-the-art ointment manufacturing plant” adds credibility to your brand—clients and consumers look for quality assurance.

Checklist Before You Buy / Engage

Even with a strong plant offering, to maximise benefits you should evaluate carefully:

Review the layout and footprint: Does the plant fit your factory space, utilities, HVAC, cleanroom requirements?

Ask for validation documents / design drawings: Are there detailed engineering drawings, fabrication certifications (for SS316L), documentation for cleaning-in-place (CIP) and change-over protocols?

Confirm capacity vs your business model: Are you going to run small volumes only or scale big? Ensure the plant size matches your growth expectations (and can be expanded).

Check packaging integration: Ointments need tube filling, jar filling, lamitube systems. Does the provider support that or will you need a separate vendor?

Evaluate service & spare parts support: Especially for critical mixers/homogenisers — downtime kills production.

Assess future flexibility: If you plan to shift formulations (e.g., from ointment to gel to cream), ensure equipment supports that without too much rework.

Review cost breakdown: Not just equipment cost, but installation, commissioning, utilities upgrade, validation cost, regulatory cost, packaging line cost.

Examine warranty / training: Will the vendor provide operator training, maintenance manuals and after-sales support?

Final Word

If you are searching for a robust, high-quality semi-solid/ointment manufacturing plant in India, the solution from Pharmachem Cosmetics Industries ticks many boxes: flexibility, compliance, scalability, reliable engineering. Whether you are a brand, a contract manufacturer, or a startup looking to launch your first line of ointments/creams, investing in such a plant gives you a strong operational foundation.

By selecting the right equipment and partner, you reduce risk, accelerate production and maintain quality — which ultimately supports your brand reputation and business growth.