PharmaChem Cosmetics Industries

is a leading Ointment Manufacturing Plant Manufacturer in India,

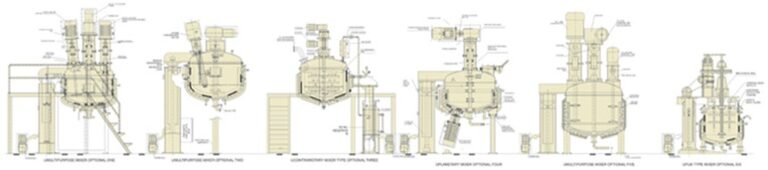

We offer state-of-the-art Ointment Manufacturing Plants designed to meet the demanding requirements of pharmaceutical and cosmetic industries. These plants are ideal for the production of ointments, creams, lotions, toothpaste, and other emulsions, ensuring efficient homogenization and consistent product quality.

The system is engineered to address two critical quality factors: minimum manual handling of ointment and negligible vacuum loss during mixing and blending, resulting in improved hygiene, uniformity, and efficient manpower utilization.

The ointment plant includes essential equipment such as a manufacturing vessel, wax phase vessel, water phase vessel, storage vessel, vacuum pump, control panel, product piping, and working platform. A material transfer pump enables smooth movement of product from the manufacturing vessel to the storage vessel and further to the ointment tube filling machine.

The plant operates as a closed-circuit system, from wax and water phase preparation to filling machine feeding, minimizing contamination risks. Materials at the required temperature are transferred under vacuum through a conical filter into the manufacturing vessel or planetary mixer. During emulsion formation, the product is recirculated through a transfer pump and discharged into the storage vessel.

The entire plant can be operated by a single operator through a centralized control panel with digital temperature and timer controls. Designed for high productivity, the system supports a minimum of two batches per shift and fully complies with cGMP standards with paint-free construction.

Ointment Manufacturing Plant Manufacturers in Maharashtra offer advanced equipment for producing a wide range of cosmetic and personal care products such as skincare, haircare, body care, perfumes, essential oils, scrubs, shower gels, lotions, creams, shampoos, conditioners, hair wax, sprays, body wash, mouthwash, and liquid soaps. The plants are supplied with working platforms, foam mixers, and transfer pumps connected to filling lines, providing complete and efficient manufacturing solutions.

Similarly, Ointment Manufacturing Plants Manufacturers and Suppliers in Gujarat deliver comprehensive systems for the cosmetic and pharmaceutical industries. Their offerings include cosmetic cream and lotion manufacturing equipment, vacuum mixer machines, lotion filling lines, face cream plants, and complete turnkey solutions. These systems support the production and filling of ointments, creams, lotions, gels, syrups, oral liquids, shampoos, toothpaste, and detergents in bottles, jars, and tubes, ensuring reliable and efficient manufacturing operations.

- 50 KGS OINTMENT MANUFACTURING PLANT

- 100 KGS OINTMENT MANUFACTURING PLANT

- 150 KGS OINTMENT MANUFACTURING PLANT

- 200 KGS OINTMENT MANUFACTURING PLANT

- 250 KGS OINTMENT MANUFACTURING PLANT

- 300 KGS OINTMENT MANUFACTURING PLANT

- 350 KGS OINTMENT MANUFACTURING PLANT

- 500 KGS OINTMENT MANUFACTURING PLANT

- 1000 KGS OINTMENT MANUFACTURING PLANT

- 1200 KGS OINTMENT MANUFACTURING PLANT

- 1500 KGS OINTMENT MANUFACTURING PLANT

- 2000 KGS OINTMENT MANUFACTURING PLANT

- 2500 KGS OINTMENT MANUFACTURING PLANT

- 3000 KGS OINTMENT MANUFACTURING PLANT

- CREAM MANUFACTURING PLANT

- LOTION MANUFACTURING VESSEL

- PASTE MIXING VESSEL

- GEL MANUFACTURING VESSEL

- MULTI MIXER

Salient Features:-

- The Plant is designed to be activated only by one operator and one helper.

- All material transfers are conducted using either vacuum systems or transfer pumps.

- All the vessels are constructed with CGMP standards, ensuring paint-free surfaces.

- The gaskets used are of silicon (food grade).

- All contact parts are crafted from S.S. 304 quality material (SS316 provided on demand), finished to class 4B (Mirror) finish, and designed to be crevice-free

- The entry for all agitators is from the top, while the High-Speed Emulsifier enters from the bottom, or customers can opt for the In-line Emulsifier as per their preference.

- All vessels are appropriate for an internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized.

- All pipes, pipe fittings, and valves are made out of SS304 / SS316 (as per customer requirement) seamless quality, internally electro-polished, with tri-clover-ended joints.

- The entire plant is furnished with CIP & SIP connections so that customers can use these facilities if they have CIP & SIP equipment.

- All values of temperature & time of the plant are shown digitally on the control panel. Ampere indicates Ampere meters.

- A microprocessor-based automatic operating plant can be built as per requirement.

- All the inlet & outlet influences are provided with tri-clover joints, which are very easy to clean & replace.

- Cosmetics cream manufacturing plant, cosmetics making plant, cosmetic blenders and filling line suitable for face creams, hand creams, sunscreen creams and Shampoo, Detergents like Dishwashing / Hand Liquid soap, etc.

Technical Specifications

| Model | PCI FBD-15 Kg | PCI FBD-30 Kg | PCI FBD-60 Kg | PCI FBD-120 Kg | PCI FBD-200 Kg | PCI FBD-250 Kg | PCI FBD-300 Kg | PCI FBD-500 Kg |

|---|---|---|---|---|---|---|---|---|

| Container Volume: Litres | 18 | 100 | 200 | 380 | 650 | 800 | 980 | 1700 |

| Batch Capacity : in Kg | 5-8 | 30-40 | 60-75 | 120-140 | 200-225 | 250-280 | 300-300 | 500-500 |

| Drying Temp C | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Motor H.P. | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 60 |

| Heating Load: KW for Electrical Heating Approximately Steam | 9 | 18 | 54 | 90 | Electrical Heating is not recommended. | |||

| Consumption Kgs/hr at Steam pressure 3 Kg/cm2 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Consumption Kgs/hr at Steam pressure 3 Kg/cm2 | 15 | 25 | 50 | 100 | 160 | 200 | 250 | 430 |