Vacuum Tray Dryers in Gujarat

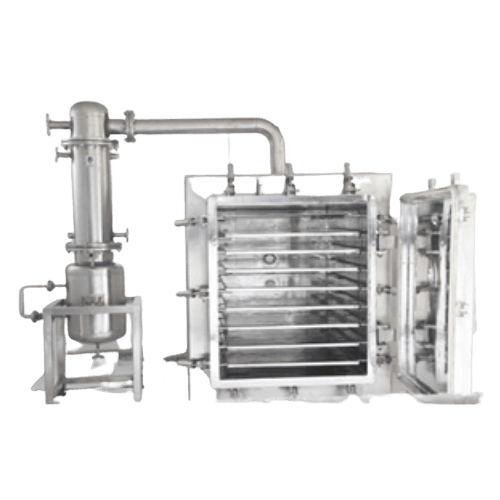

Pharmachem Cosmetics Industries is one of the leading manufacturers and exporters of Vacuum Tray Dryers (VTD) in India, offering reliable drying solutions for pharmaceutical, chemical, and food industries. Our advanced Vacuum Tray Dryer is designed to achieve uniform drying under controlled temperature and vacuum conditions, ensuring product safety, efficiency, and quality.

Contact us today for pharmachemcosmetics guidance and detailed product information. +91-8369524009

The Vacuum Tray Dryer is an essential piece of equipment widely used for drying heat-sensitive materials that may degrade or react at higher temperatures. It operates under vacuum, which lowers the boiling point of liquids, enabling drying at lower temperatures while maintaining product integrity.

What is a Vacuum Tray Dryer?

A Vacuum Tray Dryer (VTD) is a batch-type dryer that removes moisture from solid or semi-solid materials using vacuum and controlled heat. Inside the chamber, trays filled with the product are placed on shelves that are heated through conduction. The vacuum reduces pressure, allowing the moisture to evaporate at low temperatures — making it ideal for heat-sensitive or volatile materials.

This method ensures uniform drying without oxidation, contamination, or degradation of the product.

Working Principle of the Vacuum Tray Dryer

The working principle of a Vacuum Tray Dryer is based on the concept of heat transfer by conduction under vacuum. Here’s how it works:

The material to be dried is spread evenly on trays.

The chamber is sealed and vacuum is applied using a vacuum pump.

The heated shelves supply the necessary energy for moisture evaporation.

Under vacuum, the boiling point of water (or solvent) decreases, allowing it to evaporate at lower temperatures.

The vapor is condensed and collected through a condenser system.

This ensures gentle and uniform drying, retaining the quality and characteristics of the final product.

Our Presence Across Gujarat

Pharmachem Cosmetics Industries is a trusted manufacturer and supplier of Vacuum Tray Dryers in Gujarat, delivering high-performance drying solutions for pharmaceuticals, chemicals, food, and cosmetics industries. With our advanced technology and wide distribution network, we proudly serve every major industrial region across the state.

Vacuum Tray Dryers in Surat:-Reliable dryers for pharma, food, and nutraceutical industries.

Vacuum Tray Dryers in Ahmedabad:-GMP-grade dryers for bulk drugs and chemical plants.

Vacuum Tray Dryers in Rajkot:-Energy-efficient dryers for dye and engineering units.

Vacuum Tray Dryers in Vadodara:-Trusted by chemical and process industries.

Vacuum Tray Dryers in Vapi:-Ideal for cosmetic and herbal manufacturers.

Vacuum Tray Dryers in Ankleshwar:-Heavy-duty dryers for pharma and chemical units.

Vacuum Tray Dryers in Bharuch:-Effective vacuum drying for chemical industries.

Vacuum Tray Dryers in Bhavnagar:-Reliable dryers for food and chemical sectors.

Vacuum Tray Dryers in Morbi:-Used in ceramics and pharma manufacturing.

Vacuum Tray Dryers in Mehsana:-Compact dryers for mid-scale industries.

Vacuum Tray Dryers in Surendranagar:-Ensures uniform drying and high output.

Vacuum Tray Dryers in Amreli:-Efficient dryers for small manufacturing units.

Vacuum Tray Dryers in Gandhidham:-Durable dryers for industrial applications.

Vacuum Tray Dryers in Porbandar:-Dryers for food and marine processing.

Vacuum Tray Dryers in Nadiad:-Trusted by pharma and cosmetic producers.

Vacuum Tray Dryers in Dwarka:-Reliable dryers for herbal industries.

Vacuum Tray Dryers in Vasai:-Efficient batch dryers for cosmetics and food.

Vacuum Tray Dryers in Gandhinagar:–GMP-standard dryers for pharma R&D labs.

Features of Pharmachem’s Vacuum Tray Dryer

Our Vacuum Tray Dryer is designed to deliver maximum performance, efficiency, and safety. Key features include:

Stainless Steel Construction: Available in SS 304/SS 316 for superior corrosion resistance.

Uniform Heating: Shelves designed for even heat distribution.

Vacuum System: Efficient pump and condenser setup for complete moisture removal.

Temperature Control: PID-based control system for accurate heating.

Easy Cleaning & Maintenance: Smooth internal surfaces for hygiene compliance.

Explosion-Proof (Optional): For solvent-based drying operations.

Each dryer is designed and manufactured as per GMP and cGMP guidelines, making it ideal for regulated industries.

Applications of Vacuum Tray Dryer

The Vacuum Tray Dryer is used across multiple industries for drying materials that are temperature-sensitive, hygroscopic, or require precise moisture control.

Common Applications Include:

Pharmaceuticals: Drying of active ingredients (APIs), granules, and powders.

Chemicals: Drying of intermediates, catalysts, and fine chemicals.

Food Industry: Dehydration of heat-sensitive food ingredients and flavors.

Cosmetics: Drying of herbal extracts, creams, and powders.

Nutraceuticals: Drying of natural plant extracts and vitamins.

Advantages of a Vacuum Tray Dryer

Using a Vacuum Tray Dryer provides multiple operational and product benefits:

Low-Temperature Drying: Perfect for sensitive materials.

Uniform Moisture Removal: Even drying across all trays.

Shorter Drying Time: Efficient vacuum and heating system.

Improved Product Stability: Prevents oxidation or contamination.

Safe & Hygienic Design: Fully enclosed, GMP-compliant structure.

Energy Efficient: Reduced power consumption compared to conventional dryers.

These benefits make it one of the most preferred drying systems in modern pharmaceutical and chemical industries.

Technical Specifications

Pharmachem’s Vacuum Tray Dryer is available in different capacities ranging from 12 to 192 trays, depending on production requirements.

Key specifications include:

Heating Mode: Electric / Steam / Thermic Fluid

Operating Temperature: Up to 150°C

Vacuum Level: Up to 29.9” Hg

Tray Size: Standard 32” x 16” x 1.25”

Construction Material: SS 304 / SS 316

Custom models can be designed to meet specific client needs, including cleanroom compatibility and automation.

Pharmachem’s Commitment to Quality

At Pharmachem Cosmetics Industries, quality and innovation are at the core of everything we manufacture. Each Vacuum Tray Dryer is engineered using precision fabrication techniques and undergoes multiple quality inspections before dispatch.

We also provide complete documentation support for:

DQ / IQ / OQ / PQ Validation

GMP Compliance Certificates

Test Reports and Calibration Certificates

This makes our Vacuum Tray Dryer trusted by pharmaceutical and chemical manufacturers across India and abroad.

Our Supply Network Across India

Pharmachem serves industries across India with high-performance drying equipment. We supply Vacuum Tray Dryers in Gujarat, Vacuum Tray Dryers in Maharashtra, Vacuum Tray Dryers in Hyderabad, and Vacuum Tray Dryers in Tamil Nadu, supporting the diverse needs of pharmaceutical, food, and cosmetic industries nationwide.

If you’re looking for a reliable and efficient Vacuum Tray Dryer manufacturer in India, Pharmachem Cosmetics Industries is your trusted partner. Our dryers are known for quality construction, advanced design, and consistent drying performance.

Whether you are located in Gujarat, Maharashtra, Surat, or Ahmedabad, we provide tailor-made drying solutions to suit your process needs.

📞 Contact Pharmachem Cosmetics Industries today for a quotation or technical consultation for your next Vacuum Tray Dryer system.

12 Comments

100 super hot играть бесплатно https://100-super-hots.com/ awaits you with exciting moments and the chance to win big!

To really elevate an outfit, be sure to include stylish accessories.

jahonning yetakchi onlayn kazinolari qatoriga kiruvchi tashkilot . U turli xil o’yinlar va bonuslar bilan foydalanuvchilarni qiziqtiradi . 888starz onlayn kazino sifatida o’z o’yinchilariga keng tanlov imkoniyatlarini taklif etadi .

888starz скачать бесплатно https://888staruzbeki.com/apk/

??????? ?????? ?????? ??? ?????? star888 ???? ??? ?????? ????? ????????? ???????? ??? ?????? ??????????.

888starz ?? ????? ?? ??????? ????????? ?????? ????? ???? ???? ?????? ????? ?? ???????

ستارز 888 https://multitaskingmaven.com/

jest to atrakcyjna strona internetowa dla milosnikow gier kasynowych. Gracze moga wybierac sposrod wielu roznych gier, w tym slotow, gier stolowych i gier na zywo . Vulkan Spiele Casino oferuje graczom atrakcyjne bonusy i promocje .

Gra w Vulkan Spiele Casino oferuje graczom wiele korzysci, w tym dostep do szerokiej gamy gier i atrakcyjnych bonusow . Gracze moga brac udzial w programie lojalnosciowym, aby otrzymac nagrody i wyroznienia . Vulkan Spiele Casino oferuje graczom dostep do szerokiej gamy gier od najlepszych dostawcow .

vulkan spiele pl https://vulkanpoland.com/

Sam86Club is growing on me. The community is pretty active. Been enjoying myself here. Give sam86club a try

إن betfinal casino kuwait هو واحد من الأفضل المُعرّفات في مجال القمار عبر الإنترنت في الكويت . يوفّر هذا الكازينو مجموعة واسعة من الألعاب المسلية والمربحة، مما يجعل تجربة اللاعبين ممتعة ومليئة بالإثارة. يتمتع اللاعبون في betfinal casino kuwait بسرعة وسهولة في اللعب بفضل التقنيات الحديثة.

كازينو بت فاينل https://betfinal-kw.com/

يشدّد betfinal casino kuwait على أهمية الحفاظ على أمان وسلامة المعلومات الشخصية والمالية للجميع. يحرص الكازينو على تزويد اللاعبين بتجربة آمنة ومحميّة، مما يمنحهم الثقة الكافية للاندماج في الألعاب المختلفة.

Czasami bardzo popularne kasyno online . Oferuje ono duzy wybor gier, ktore sa dostepne online. Jednym z najwiekszych atutow tego kasyna jest to, ze oferuje ono bardzo duzy wybor gier stolowych .

vulkanspiele casino bonus ohne einzahlung vulkanspiele casino bonus ohne einzahlung.

Vulkan Spiele Casino jest czesto wybierane przez milosnikow hazardu . Gracze moga grac w wiele roznych gier, ktore sa dostepne online. Jednym z najwiekszych atutow tego kasyna jest to, ze oferuje ono bardzo duze wygrane .

Es prasentiert eine gro?e Auswahl an verschiedenen Spielen. Das Casino ist bekannt fur seine benutzerfreundliche Oberflache seine leicht zu bedienende Oberflache und seine sicheren Zahlungsmethoden seine verschiedenen und sicheren Zahlungsoptionen. Die Spieler konnen zwischen verschiedenen Arten von Spielen wahlen konnen zwischen verschiedenen Spieltypen wahlen .

bahigo svizzera https://bahigosch.com/

Das Bahigo Casino bietet auch eine Vielzahl von Bonusangeboten bietet verschiedene Bonusangebote an . Die Spieler konnen von Willkommensboni profitieren konnen von Einzahlungsboni profitieren , die ihre Chancen auf Gewinne erhohen ihre Chancen auf Gewinne verbessern . Daruber hinaus bietet das Casino auch eine loyale Spieler community eine engagierte Spielercommunity.

Con un’enorme varieta di opzioni per i giocatori . In questo scenario, il Crazy Time Casino Slot Italy e un punto di riferimento per gli appassionati di giochi d’azzardo . I giocatori italiani possono ora godere di una vasta gamma di giochi, inclusi il Crazy Time Casino Slot .

demo crazytime https://crazytime-italia.com/

La scelta di giocare al Crazy Time Casino Slot Italy offre ai giocatori una grande varieta di benefici, tra cui la possibilita di vincere premi in denaro . I giocatori possono scegliere tra diverse opzioni di pagamento e di ritiro, rendendo l’esperienza di gioco ancora piu conveniente .

??? 888starz casino ?????? ?? ???? ??????????? ??? ???????? ? ??? ????? ??????? ??????? ??? ???????? ????????? ?????????? ??? ?? ????. ????? ??? ?????? ????? ??????? ?? ??????? ???? ??????? ??????? ? ??? ?? ??? ??????? ???????? ?????? ???? ?????? ??????. ????? experience ????? ?? 888starz casino ???? ??????? ??????? ????????? ??? ???? ???????? ??????? ?? ???????? ??????? ?????? ????? ???????? ???????.

?????? 888starz casino ?? ??????????? ???????? ???secure ? ??? ????? ????? ????? ?????? ???? ??? ??? ???? ??????. ???? ???????? ??????? ?? ???? ????? ??? ?????? ?? ?????? ??????????? ??? ??? ????? ???? ??????????? ???????? ????? ???????. ????? ?????? ?? 888starz casino ???? ??????? ??????? ????????? ??? ???? ???????? ????? ????? ???????? ??????? ???????? ?? ???????? ???????.

تحميل 888starz https://888starzegypt2026.com/apk/

يمكنك الآن الاستمتاع بالمراهنات الرياضية ومجموعة واسعة من الألعاب عبر الإنترنت من خلال زيارة 888starz egypt واستخدام كافة الخدمات والفرص المتاحة.

يعتبر 888starz egypt خيارًا رائعًا للعبة القمار . ويتميز بتوفير مجموعة واسعة من الألعاب، بما في ذلك ألعاب الطاولة وألعاب البوكر وعجلة الحظ. يوفر 888starz egypt حماية قوية للمستخدمين. ويتماشى ذلك مع الحفاظ على سرية المعلومات الشخصية للمستخدمين.

تتميز منصة 888starz egypt بالأمانة والشفافية . ويتم تحقيق ذلك من خلال توفير خدمات دعم فني متقدم. يمكن للمستخدمين الوصول إلى دعم فني في 888starz egypt. ويتم توفير ذلك لضمان تجربة لعبة رائعة للمستخدمين.

**القسم الثاني: مميزات 888starz egypt**

يوفر 888starz egypt ألعابًا متنوعة . ويتم توفير ألعاب بجانب ألعاب الطاولة وألعاب البوكر. تتميز منصة 888starz egypt بلعبة البوكر. ويتم توفير خدمات دعم فني لتنظيم هذه الألعاب.

يمكن للمستخدمين الوصول إلى 888starz egypt من خلال الهواتف المحمولة . ويتم توفير تطبيق leichtสำหร يمكن تحميله على الهواتف المحمولة. يتميز تطبيق 888starz egypt بالسرعة والكفاءة . ويتم توفير ذلك لضمان تجربة لعبة رائعة للمستخدمين.

**القسم الثالث: الخدمات التي يقدمها 888starz egypt**

يتميز 888starz egypt بتوفير خدمات دعم فني متقدم . ويتم توفير خدمات دعم فني لتنظيم الألعاب. يعتبر الدعم الفني في 888starz egypt رائعًا. ويتم توفير خدمات دعم فني لتنظيم الألعاب.

يمكن للمستخدمين الوصول إلى خدمات الدعم الفني في 888starz egypt بسهولة . ويتم توفير خدمات دعم فني على مدار الساعة. يتميز 888starz egypt بتوفير خدمات دعم فني على مدار الساعة . ويتم توفير خدمات دعم فني لضمان تجربة لعبة رائعة للمستخدمين.

888starz egypt https://sites.google.com/view/888starz-egypt/

888starz مصر تهتم برعايه العملاء و توفير تجربة مميزه لهم

888bet تحميل https://888starz.onl/eg/apk/

888starz Egypt تُمكن المستخدمين من المشاركة في بطولات دولية ومحلية